As a woodworker, you may have come across the need to work with epoxy resin. Whether you’re building a charcuterie board or a river table, you may need to plane epoxy resin to achieve a smooth surface. But can you plane epoxy resin? The short answer is yes, but there are some important factors to consider before you begin.

Understanding the properties of epoxy resin is crucial before you start planing it. Epoxy resin is a two-part adhesive that consists of a resin and a hardener. It’s a durable and versatile material that’s commonly used in woodworking projects. However, it’s also a hard and tough material that can be challenging to work with. Therefore, it’s important to use the right tools and techniques to plane epoxy resin effectively.

Key Takeaways

- Epoxy resin can be planed using the right tools and techniques.

- Proper preparation and safety measures are crucial before planing epoxy resin.

- Post-planing epoxy resin requires polishing and finishing for a smooth surface.

Understanding Epoxy and Its Properties

https://www.youtube.com/watch?v=sJ_IMc0n78s&embed=true

As a woodworker, it’s important to understand the properties of epoxy and epoxy resin. Epoxy is a type of polymer that is known for its strong adhesive properties and is commonly used in woodworking for bonding different materials together. Epoxy resin is a two-part system that consists of a resin and a hardener. When these two components are mixed together, they create a chemical reaction that results in a hard, durable material.

One of the most important things to understand about epoxy is the ratios. It’s crucial to mix the resin and hardener in the correct proportions to ensure that the epoxy cures properly. If the ratio is off, the epoxy may not cure at all or may cure too slowly, resulting in a weaker bond. It’s also important to note that epoxy has a limited working time, so it’s essential to work quickly and efficiently.

In addition to its adhesive properties, epoxy is also commonly used as a coating. Epoxy coatings are known for their durability and resistance to chemicals and moisture. They are often used on floors, countertops, and other surfaces that require a tough, protective layer.

When it comes to adhesives and coatings, epoxy is a top choice for many woodworkers due to its strength and durability. However, it’s important to note that epoxy can be tricky to work with. It has a relatively low melting point and is soft in nature, which can make it difficult to plane. It’s possible to plane epoxy, but it requires a delicate touch and a steady hand.

Overall, understanding the properties of epoxy and epoxy resin is essential for any woodworker. Whether you’re using it as an adhesive or a coating, it’s important to follow the proper mixing ratios and work quickly to ensure a strong bond or a durable finish.

Preparation and Tools Required

https://www.youtube.com/watch?v=iozjWOjyjyw&embed=true

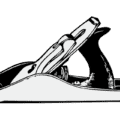

Before you start planing epoxy, you need to prepare a few things. First, make sure you have a sturdy workbench or table to work on. It should be large enough to accommodate the size of your project. You will also need a planer, which is a woodworking tool used to remove material from a surface.

In addition to a planer, you may need other tools such as a hand plane, router, scraper, orbital sander, belt sander, drum sander, or knives. The specific tools you need will depend on the size and shape of your project. For example, a hand plane may be useful for smaller projects or for smoothing out edges, while a belt sander may be necessary for larger projects or for removing more material.

When choosing a planer, make sure it is designed to handle epoxy. Some planers may not be able to handle the soft nature and low melting point of epoxy, which can result in damage to the planer. Look for a planer with a spiral cutter block or carbide cutters, which are more durable and can handle the challenges of planing epoxy.

In addition to the right tools, you will also need to take safety precautions when working with epoxy. Wear protective gloves, goggles, and a respirator to prevent exposure to the fumes and dust. Make sure your work area is well-ventilated and keep a fire extinguisher nearby in case of accidental ignition.

Overall, planing epoxy requires careful preparation and the right tools. With the proper equipment and safety precautions, you can achieve the desired results for your project.

Process of Planing Epoxy

https://www.youtube.com/watch?v=dUdwJPzcLWQ&embed=true

Planing epoxy can be a tricky process, but it is possible with the right tools and techniques. Here are some steps to follow for planing epoxy:

Step 1: Sand the Epoxy

Before planing the epoxy, it is important to sand it down to a smooth surface. This will prevent the blade from getting damaged or gummed up. Use sandpaper with a grit of 80 or lower to remove any bumps or high spots in the epoxy.

Step 2: Adjust Blade Angle and Feed Rate

When planing epoxy, it is important to adjust the blade angle and feed rate to prevent tearing or chipping. A low blade angle of around 15 degrees is recommended, as well as a slow feed rate to prevent material removal.

Step 3: Check Moisture Content and Temperature

Moisture content and temperature can affect the planing process. Make sure the epoxy is completely dry and has a moisture content of less than 10%. Also, avoid planing epoxy in temperatures below 60°F or above 80°F to prevent cracking or melting.

Step 4: Use a Spiral Cutter Block

A spiral cutter block is recommended for planing epoxy, as it reduces tear-out and produces a smoother finish. This type of blade also lasts longer than traditional straight blades.

Step 5: Clean Blade Frequently

It is important to clean the blade frequently when planing epoxy to prevent buildup and damage. Use a scraper or cleaning solution to remove any residue from the blade.

By following these steps and using the right tools, planing epoxy can be a successful process. Remember to take your time and be patient, as it may take some trial and error to achieve the desired results.

Safety Measures While Planing Epoxy

https://www.youtube.com/watch?v=up9cAMq9v5A&embed=true

As epoxy is a soft material with a low melting point, it can be tricky to plane it without causing damage to the surface. Therefore, it is essential to take proper safety measures while planing epoxy to avoid any potential risks. In this section, I will discuss the safety precautions and guidelines that you should follow while planing epoxy.

Safety Precautions

The safety precautions required when planing epoxy include wearing face masks, eye goggles, gloves, and safety shoes. It is also recommended to wear long-sleeved shirts and pants to protect your skin from any contact with the epoxy. The dust and fumes produced while planing epoxy can be harmful to your respiratory system, eyes, and skin. Therefore, it is essential to protect yourself from these hazards.

Safety Concerns

One of the major safety concerns while planing epoxy is the heat generated by the cutters. The heat can melt the epoxy’s surface, causing the cutters to gum up and potentially damage the surface. Therefore, it is important to use sharp cutters and take frequent breaks to avoid overheating.

Another safety concern is the potential for the epoxy to chip or crack while planing, which can cause injury if the pieces fly off. To prevent this, it is recommended to use a slow and steady pace while planing and to secure the epoxy firmly to the workbench.

Guidelines

To plane epoxy safely, it is important to follow these guidelines:

- Use a sharp cutter to avoid overheating and damaging the surface

- Take frequent breaks to prevent overheating

- Wear protective gear such as face masks, eye goggles, gloves, and safety shoes

- Secure the epoxy firmly to the workbench to prevent chipping or cracking

- Use a slow and steady pace while planing to prevent injury

By following these safety precautions and guidelines, you can safely plane epoxy without any potential risks.

Post Planing Epoxy: Polishing and Finishing

https://www.youtube.com/watch?v=9-WYOK90KNo&embed=true

After planing epoxy, the surface may appear dull and scratched. To achieve a smooth and glossy finish, polishing is required.

Polishing can be done using a variety of materials such as sandpaper, polishing compound, or a buffing wheel. I prefer using a buffing wheel with a polishing compound as it provides a faster and more efficient way to achieve a high-gloss finish.

Before polishing, it is important to clean the surface of any dust or debris. I recommend using a tack cloth to wipe down the surface thoroughly.

Once the surface is clean, I start with a low grit polishing compound and work my way up to a higher grit for a finer finish. The grits I use typically range from 400 to 2000. It is important to note that the higher the grit, the finer the finish.

After polishing, the surface can be sealed with a lacquer or polyurethane. Lacquer is a quick-drying and durable finish that provides a high-gloss shine. Polyurethane is a slower-drying finish that is more durable and resistant to scratches and wear.

When applying the finish, it is important to follow the manufacturer’s instructions carefully. I typically apply two to three coats of the finish, allowing each coat to dry completely before applying the next.

In conclusion, planing epoxy is only the first step in achieving a smooth and glossy finish. Polishing and finishing are equally important to achieve the desired result. With the right tools and techniques, anyone can achieve a professional-looking finish on their epoxy projects.

Transporting Epoxy: Guidelines and Restrictions

As someone who frequently works with epoxy, I have had to transport it on several occasions. Whether I am traveling for work or shipping a project to its final destination, I always make sure to follow the guidelines and restrictions set by the TSA and other regulatory bodies.

When it comes to traveling with epoxy on a plane, there are specific rules and regulations that you need to follow. The TSA has strict guidelines regarding liquids, aerosols, gels, creams, and pastes in carry-on bags. According to the TSA, containers holding more than 3.4 ounces (100 milliliters) of liquid are not allowed in carry-on luggage. This applies to epoxy resin as well. If your epoxy container holds more than 3 ounces, then it can be taken on a plane, but it must be placed in your checked baggage.

It is important to note that epoxy resin is considered a hazardous material and is subject to certain restrictions. It is classified as a Class 3 flammable liquid, which means that it can ignite easily and poses a fire hazard. As such, it must be properly packaged and labeled when transported.

When shipping epoxy resin, it is important to use proper packaging materials to ensure that it does not leak or spill during transit. The packaging must be strong enough to withstand the rigors of shipping and should be clearly labeled as containing hazardous materials.

In addition to the TSA guidelines, it is important to check the regulations of your destination country or state. Some countries have stricter regulations regarding hazardous materials, and it is important to be aware of these before traveling or shipping your epoxy.

Overall, transporting epoxy resin requires careful attention to detail and adherence to strict guidelines and regulations. By following these guidelines, you can ensure that your epoxy arrives at its destination safely and without incident.

Epoxy in Automotive and Aviation Industries

As an AI language model, I don’t have personal experience with epoxy in the automotive and aviation industries. However, I have researched and found that epoxy is widely used in both of these industries due to its excellent adhesive and mechanical properties.

In the automotive industry, epoxy is used as a structural adhesive to bond various components together. For example, it is used to bond body panels, windshields, and other parts of the car. Epoxy is also used to repair cracks and damages in the car body. It is preferred over other adhesives because of its high strength, durability, and resistance to chemicals and temperature.

In the aviation industry, epoxy is used to manufacture aircraft parts such as wings, fuselage, and empennage assemblies. Modern planes such as Boeing 787 and Airbus A380 utilize carbon fiber reinforced epoxy composites in the aircraft fuselage, wings, and empennage assemblies. Epoxy composites offer several advantages over metals, including high strength-to-weight ratio, corrosion resistance, and low thermal expansion. Epoxy is also used as a structural adhesive in aircraft production. It is preferred because of its excellent bonding properties and resistance to temperature and chemicals.

Epoxy is also used in the production of resin tables. These tables are made by pouring epoxy resin over a surface and allowing it to cure. The result is a durable, glossy, and waterproof surface. The resin can be tinted to create various colors and patterns. Resin tables are becoming increasingly popular due to their unique appearance and durability.

Overall, epoxy is a versatile and reliable material that is used in various industries. Its excellent adhesive and mechanical properties make it a preferred material for bonding and manufacturing applications.

Frequently Asked Questions

What is the best tool to plane epoxy resin?

The best tool to plane epoxy resin is a hand plane or a belt sander. Hand planes are the most precise tool to use, but they require some skill to use effectively. Belt sanders are more forgiving and can remove material quickly, but they can also be aggressive and remove too much material if not used carefully.

Can a DeWalt planer be used to plane epoxy?

Yes, a DeWalt planer can be used to plane epoxy, but it requires some special considerations. Epoxy is a relatively soft material, so the blades on the planer need to be sharp and set to a shallow depth of cut. Additionally, the epoxy surface needs to be supported to prevent it from chipping or breaking during planing.

Is it safe to use a thickness planer on cured epoxy?

No, it is not safe to use a thickness planer on cured epoxy. The blades on a thickness planer are designed to remove a lot of material quickly, and they can easily chip or break the epoxy surface. Additionally, the epoxy can clog the planer’s dust collection system, causing damage to the machine.

What is a router sled and can it be used to plane epoxy?

A router sled is a jig that holds a router and allows it to move back and forth over a workpiece. It is commonly used to flatten large slabs of wood, but it can also be used to plane epoxy. The router sled removes material slowly and precisely, making it an effective tool for leveling epoxy surfaces.

How long should epoxy resin cure before being planed?

Epoxy resin should cure for at least 24 hours before being planed. Planing epoxy that is not fully cured can cause the surface to tear or chip, resulting in a rough finish. It is best to wait until the epoxy is fully cured before attempting to plane it.

What is the best method to level cured epoxy resin?

The best method to level cured epoxy resin is to use a combination of hand planes and sandpaper. Start by using a hand plane to remove the high spots, then switch to sandpaper to smooth out the surface. Repeat this process until the surface is level and smooth. For larger surfaces, a router sled can be used to remove material quickly and precisely.

Hi, I’m Sal Muller of Tooltrip.com. My DIY experience led me to understand essential power tools for home projects. Tooltrip.com guides enthusiasts and professionals in choosing right tools for any job. I provide concise top tool reviews for easier, efficient DIY.