Drywall is a popular building material that is used to create walls and ceilings in modern construction. It is an essential component of most homes and commercial buildings, and it is important to understand what it is made of and how it is manufactured. In this article, I will provide a brief overview of the composition and manufacture of drywall, as well as its physical characteristics, installation, and repair.

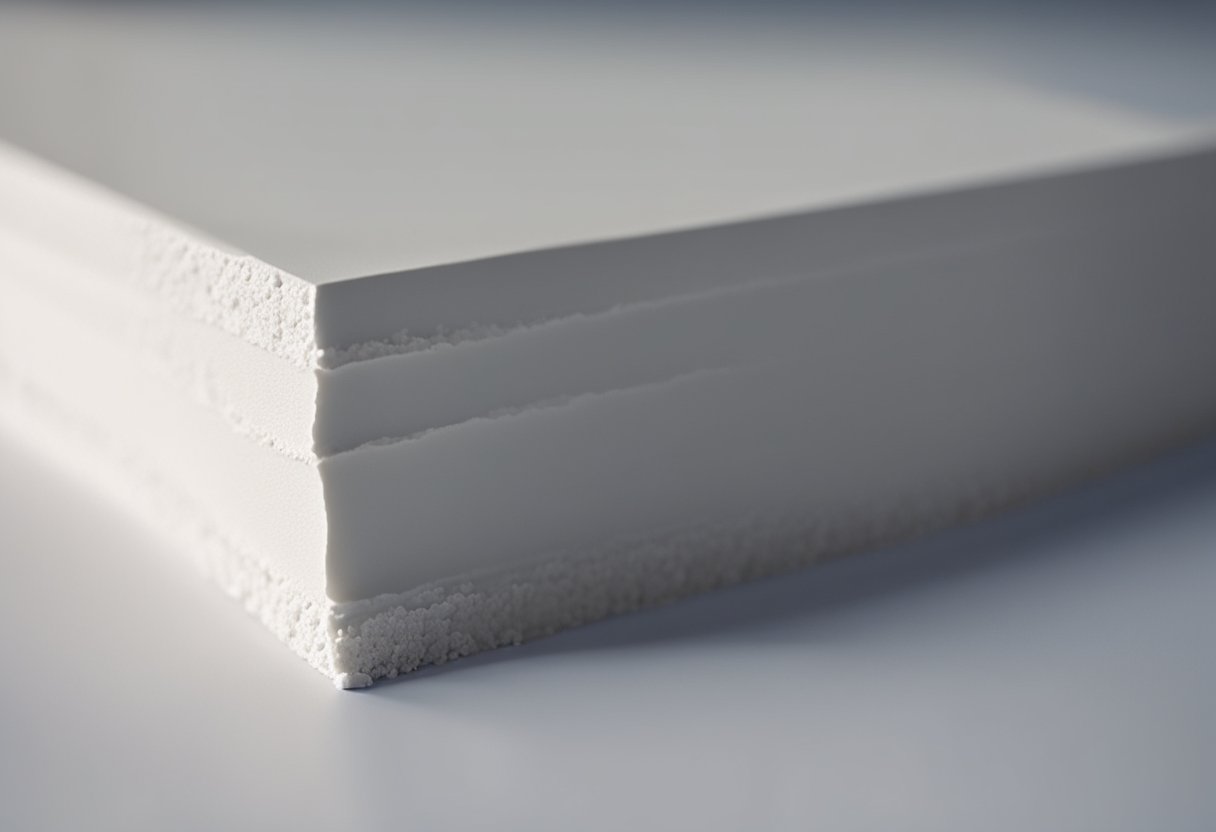

Drywall, also known as gypsum board or plasterboard, is made of a core of gypsum plaster sandwiched between two layers of heavy paper or fiberglass. Gypsum is a soft sulfate mineral that is commonly found in sedimentary rock formations. It is mined, crushed, and then heated to remove the water content, resulting in a fine powder that is then mixed with water to create a paste. This paste is then poured onto the paper or fiberglass sheets and allowed to dry, creating a rigid and durable panel that can be cut, shaped, and installed with ease.

History of Drywall

https://www.youtube.com/watch?v=o6uPjGTyogM&embed=true

I’ve always been fascinated by the history of drywall, which is a common building material used for walls and ceilings. Drywall, also known as plasterboard, gypsum board, or wallboard, was invented in the early 20th century.

The United States Gypsum Company (USG) is credited with inventing drywall in 1916. It was originally called “Sackett Board” after the inventor Augustine Sackett, but later renamed “Sheetrock” by USG. The original drywall was made from a layer of gypsum plaster sandwiched between two sheets of heavy paper.

During World War II, the use of drywall became more widespread due to a shortage of construction materials. The USG Company even created a special type of drywall that was fire-resistant and could be used in military buildings.

Over time, drywall became the standard material used for walls and ceilings in residential and commercial construction. Today, it is estimated that over 90% of homes in the United States have drywall walls and ceilings.

The manufacturing process for drywall has also evolved over time. Modern drywall is made by mixing gypsum plaster with water and various additives, then pouring the mixture onto a sheet of paper. The paper is then covered with another sheet of paper and pressed together to create a strong, durable board.

In conclusion, the history of drywall is a fascinating one that spans over a century. From its humble beginnings as a wartime building material to its current status as the standard for walls and ceilings, drywall has come a long way.

Composition and Manufacture

https://www.youtube.com/watch?v=bJaCekq4xwc&embed=true

Drywall is a construction material that is used to create walls and ceilings in buildings. It is composed of several different materials, including gypsum, water, and various additives.

The primary component of drywall is gypsum, which is a soft mineral composed of calcium sulfate dihydrate. Gypsum is found in large deposits throughout the world and is mined from quarries or underground mines. Once mined, the gypsum is crushed into a fine powder and then heated to remove the majority of the water content. This process, known as calcination, creates a dry powder that is mixed with water to create a paste.

To create drywall panels, the gypsum paste is sandwiched between two sheets of heavy paper or fiberglass. The resulting panel is then dried in a temperature-controlled chamber until it is hard and rigid. The paper or fiberglass facing on the panels provides a smooth surface that can be painted or wallpapered.

In addition to gypsum and water, drywall may contain a variety of additives to improve its properties. These additives can include starch, boric acid, sulfur, and limestone. Some manufacturers also use recycled materials in the production of drywall to reduce waste and environmental impact.

Overall, the composition and manufacture of drywall is a relatively simple process that results in a durable and versatile building material.

Types of Drywall

https://www.youtube.com/watch?v=La9Gr4vvvgA&embed=true

As I mentioned earlier, drywall is a construction material made of gypsum plaster and cellulose or fiberglass as its main ingredients. There are several types of drywall available in the market, and each type has its own unique features and benefits.

Regular Drywall

Regular drywall, also known as gypsum board, is the most common type of drywall used in construction. It is made of gypsum plaster that is sandwiched between two sheets of heavy paper. This type of drywall is versatile and can be used for walls and ceilings in most areas of a house.

Paperless Drywall

Paperless drywall, also known as fiberglass-faced drywall, is similar to regular drywall but has a fiberglass mat instead of paper on both sides. This type of drywall is moisture-resistant and is a good choice for areas that are prone to mold and mildew, such as bathrooms and basements.

Soundproof Drywall

Soundproof drywall, also known as acoustic drywall, is designed to reduce noise transmission between rooms. It has a dense core that is made of gypsum plaster and other materials, which helps to absorb sound waves. This type of drywall is ideal for home theaters, music rooms, and bedrooms.

Fire-Resistant Drywall

Fire-resistant drywall, also known as Type X drywall, is designed to slow down the spread of fire. It has special additives that help it to resist fire for a longer period of time than regular drywall. This type of drywall is required by building codes in areas where fire safety is a concern, such as garages, furnace rooms, and stairwells.

Mold-Resistant Drywall

Mold-resistant drywall, also known as moisture-resistant drywall, is designed to prevent the growth of mold and mildew. It has a special coating that resists moisture and is a good choice for areas that are prone to water damage, such as bathrooms, kitchens, and laundry rooms.

Blue Board Drywall

Blue board drywall, also known as plaster baseboard, is used for veneer plastering. It has a special paper facing that is designed to bond with plaster. This type of drywall is often used in areas where a smooth, seamless finish is desired, such as living rooms, dining rooms, and bedrooms.

Veneer Plastering

Veneer plastering is a technique used to create a smooth, seamless finish on walls and ceilings. It involves applying a thin layer of plaster over blue board drywall. This type of finish is durable and easy to maintain, and is often used in high-end homes and commercial buildings.

Gypsum Plaster

Gypsum plaster, also known as plaster of Paris, is a type of plaster made from gypsum. It is used to create decorative finishes on walls and ceilings, and is often used in historical buildings and homes.

In conclusion, drywall is a versatile and durable construction material that comes in many different types. Each type has its own unique features and benefits, and choosing the right type of drywall for your project can help you achieve the desired results.

Physical Characteristics

Drywall is a popular building material that is widely used in construction projects. It is made of gypsum plaster and cellulose or fiberglass as its main ingredients. Drywall panels, also known as wallboard, plasterboard, gypsum board, or Sheetrock, are created by sandwiching a core layer of wet gypsum plaster between heavy paper or fiberglass surface sheets and then hardening them in drying chambers.

Drywall panels come in various sizes, thicknesses, and widths. The most common size is 4 feet by 8 feet, with a thickness of 1/2 inch or 5/8 inch. However, other sizes are also available, including 4 feet by 12 feet, 4 feet by 10 feet, and 4 feet by 16 feet. The width of the panels can vary depending on the manufacturer and the intended use.

Drywall panels can be found in a variety of colors, but the most common color is white. However, some manufacturers offer panels in other colors, such as beige or gray.

One of the most important physical characteristics of drywall is its strength. The strength of drywall panels is determined by the thickness of the gypsum core and the type of paper or fiberglass used on the surface sheets. Thicker gypsum cores and stronger surface sheets result in stronger panels that are more resistant to damage.

Overall, drywall panels are a versatile and durable building material that is used in a wide variety of construction projects. They are available in a range of sizes, thicknesses, and colors, and their strength can be customized to suit the needs of the project.

Installation and Repair

When it comes to installing drywall for walls or ceilings, there are a few key things to keep in mind. First, make sure that the framing is properly spaced and level. This will ensure that the drywall lays flat and looks smooth once it is installed.

Next, measure and cut the drywall to fit the space. Use a keyhole saw to cut out any openings for electrical outlets or light switches. Once the drywall is cut to size, it can be installed using nails or screws. Be sure to use the appropriate size and spacing for the nails or screws, as this will affect the strength and stability of the installation.

After the drywall is installed, it’s time to cover the joints with joint compound. This is a type of plaster that is used to fill in the gaps between the sheets of drywall. Apply the joint compound with a trowel, making sure to smooth it out as much as possible. Once the joint compound is dry, sand it down to create a smooth surface. Repeat this process until the joints are completely covered and smooth.

To reinforce the joints, drywall tape can be applied over the joint compound. This will add extra strength and stability to the installation. Simply press the tape into the compound and smooth it out. Once the tape is in place, apply another layer of joint compound to cover it.

If you need to repair drywall, the process is similar to installation. First, cut out the damaged area using a keyhole saw. Then, cut a piece of drywall to fit the opening and install it using nails or screws. Cover the joints with joint compound and drywall tape, just like with installation. Sand down the surface and apply paint or texture as needed.

Overall, installing and repairing drywall is a straightforward process that requires attention to detail and the right tools. With a little practice, anyone can achieve a professional-looking result.

Safety and Insulation

When it comes to safety, drywall is a popular choice for building construction due to its fire-resistant qualities. The primary ingredient of drywall is gypsum, a naturally occurring mineral that contains calcium sulfate dihydrate. The addition of water to gypsum results in a hardened core, creating a sturdy and resilient surface.

Drywall is also an excellent insulator, making it a popular choice for homes and buildings. It is an effective thermal insulator, keeping the indoor temperature comfortable and reducing energy costs. Additionally, it is a sound insulator, reducing noise levels between rooms and floors.

However, it is important to take precautions when installing drywall. The compounds used in joints contain elements such as talc, calcite, mica, gypsum, silica, and even high-risk items such as mercury. When these sometimes-toxic particles are inhaled, upper respiratory conditions such as asthma and lung cancer can result. Therefore, it is crucial to use proper personal protective equipment (PPE) when installing drywall, such as a dust mask, safety goggles, and gloves.

Drywall is also water-resistant, but it is not completely waterproof. If exposed to water, drywall can absorb moisture and become damaged, leading to mold and mildew growth. To prevent this, it is essential to use water-resistant drywall in areas prone to moisture, such as bathrooms and kitchens.

In summary, drywall is a safe and effective building material that provides excellent insulation and fire resistance. However, it is crucial to take precautions when installing it to avoid potential health hazards. Additionally, it is important to use water-resistant drywall in areas prone to moisture to prevent mold and mildew growth.

Environmental Impact and Sustainability

As a construction material, drywall has a significant environmental impact. It is one of the highest generators of greenhouse gases, along with steel and cement. This is largely due to the high amount of energy required to mine, transport, and manufacture the gypsum used in drywall production. However, there are some eco-friendly alternatives available that can reduce the environmental impact of drywall.

One such alternative is EcoRock, a sustainable drywall made by Serious Materials. EcoRock is made from 80% recycled materials, including fly ash, slag, and kiln dust, which are byproducts of industrial processes. The manufacturing process requires just 20% of the energy of traditional kiln firing, and does not rely upon ovens. This makes EcoRock a more sustainable option than traditional drywall.

Another way to reduce the environmental impact of drywall is to recycle it. Drywall is biodegradable, so it can be added to compost bins to decompose. It can also be sold to local construction or renovation companies for reuse. However, many landfills are hesitant to take drywall because it can become a breeding ground for mold and pests.

In addition, there are eco-friendly drywall materials available that use natural materials such as paper pulp, perlite, and silica instead of gypsum. These materials are renewable and have a lower environmental impact than traditional drywall. Some eco-friendly drywall products also use polymers and adhesives to reduce the amount of gypsum needed, further reducing their environmental impact.

Overall, while traditional drywall has a significant environmental impact, there are eco-friendly alternatives available that can reduce its impact on the environment.

Frequently Asked Questions

What materials are commonly used to make drywall?

Drywall is made from gypsum, which is a soft sulfate mineral. The gypsum is then mixed with additives such as starch, paper pulp, and other materials to improve its strength and durability. The outer layer of drywall is made from heavy paper or fiberglass sheets, which are then hardened in drying chambers.

What is the main component of drywall?

The main component of drywall is gypsum, which is a naturally occurring mineral. Gypsum is a soft sulfate mineral that is commonly used in construction because of its fire-resistant properties. Gypsum is also used in the production of cement, plaster, and other building materials.

Are there any toxic materials used in drywall production?

Drywall production does not involve the use of toxic materials. However, some drywall products may contain trace amounts of naturally occurring elements such as arsenic, lead, and mercury. These elements are found in the raw materials used to make drywall and are not added intentionally.

How is drywall different from other types of wall materials?

Drywall is different from other types of wall materials such as plaster and concrete because it is easier to install and less expensive. Drywall is also more fire-resistant than other wall materials, making it a popular choice for residential and commercial construction.

What is the process for making drywall?

The process for making drywall involves mixing gypsum with additives such as starch, paper pulp, and other materials to improve its strength and durability. The mixture is then poured onto a sheet of heavy paper or fiberglass and allowed to dry. The resulting sheet is then cut to size and finished with a smooth surface.

Is there a difference between regular and fire-rated drywall?

Yes, there is a difference between regular and fire-rated drywall. Fire-rated drywall is designed to resist the spread of fire and smoke. It is made with special additives that help it to resist flames and heat. Regular drywall does not have these additives and is not as fire-resistant.

Hi, I’m Sal Muller of Tooltrip.com. My DIY experience led me to understand essential power tools for home projects. Tooltrip.com guides enthusiasts and professionals in choosing right tools for any job. I provide concise top tool reviews for easier, efficient DIY.