Diamond drill bits are a type of drill bit that are used to create holes in hard materials such as glass, porcelain, and stone. They are made with small pieces of diamond powder that are embedded in the tip of the bit, giving them the ability to cut through tough materials with ease. Diamond drill bits come in a variety of shapes and sizes, making them a versatile tool for a range of applications.

Understanding diamond drill bits is essential for anyone who wants to use them effectively. These bits are different from other types of drill bits because they are made with diamond powder, which is one of the hardest materials in the world. This makes them ideal for drilling through hard materials like glass, stone, and ceramics, which can be difficult to drill through with other types of bits. Diamond drill bits are also more durable than other types of bits, making them a good investment for anyone who needs to drill through hard materials on a regular basis.

Key Takeaways

- Diamond drill bits are made with small pieces of diamond powder that are embedded in the tip of the bit, giving them the ability to cut through tough materials with ease.

- These bits are different from other types of drill bits because they are made with diamond powder, which is one of the hardest materials in the world.

- Diamond drill bits are ideal for drilling through hard materials like glass, stone, and ceramics, and are more durable than other types of bits.

Understanding Diamond Drill Bits

I have been using diamond drill bits for several years now, and I can confidently say that they are one of the most versatile and durable types of drill bits available. Diamond drill bits are specifically designed to cut through hard materials such as glass, stone, ceramic, porcelain, and even granite.

Diamond drill bits are made from a combination of steel and diamond particles, which are bonded together to form a hard, durable cutting edge. The diamond particles are embedded in the steel matrix, providing a sharp cutting edge that can easily cut through hard materials.

One of the most significant advantages of diamond drill bits is their ability to maintain their sharpness for an extended period. Unlike traditional drill bits that can become dull and ineffective after a few uses, diamond drill bits can last for hundreds of uses, making them a cost-effective option in the long run.

Diamond drill bits come in various shapes and sizes, including cylindrical, conical, and spherical. The shape of the drill bit depends on the type of material being drilled and the size of the hole required.

When using diamond drill bits, it is essential to use them at a relatively slow speed and with a constant supply of water. The water helps to cool the bit and lubricate the cutting edge, preventing it from overheating and becoming damaged.

In summary, diamond drill bits are a reliable and versatile tool that can cut through hard materials with ease. They are durable, cost-effective, and come in various shapes and sizes, making them suitable for a wide range of applications.

The Composition of Diamond Drill Bits

Diamond drill bits are made of a combination of steel and diamond powder. The diamond powder is used to create the cutting edge of the drill bit, which is what allows it to cut through hard materials such as glass, stone, and ceramics. The steel is used to create the body of the drill bit, providing strength and durability.

The diamond powder used in the manufacturing of diamond drill bits is typically synthetic and made through a process called high-pressure high-temperature (HPHT) synthesis. During this process, carbon is subjected to extreme heat and pressure, causing it to crystallize into diamonds. These diamonds are then ground into a fine powder and used to coat the cutting edge of the drill bit.

The amount of diamond powder used in the manufacturing of a diamond drill bit can vary depending on the intended use of the bit. Higher-quality bits will typically have a higher concentration of diamond powder, which allows them to cut through harder materials more efficiently.

It’s important to note that not all diamond drill bits are created equal. The quality of the diamond powder, as well as the manufacturing process used, can greatly affect the performance and durability of the bit. When selecting a diamond drill bit, it’s important to look for one that is made from high-quality materials and has been manufactured using a reliable process.

In summary, diamond drill bits are made from a combination of steel and diamond powder. The diamond powder is used to create the cutting edge of the bit, while the steel provides strength and durability. The quality of the diamond powder and the manufacturing process used can greatly affect the performance and durability of the bit.

Types of Diamond Drill Bits

There are different types of diamond drill bits available in the market, each designed to meet specific drilling needs. In this section, I will discuss some of the most common types of diamond drill bits.

1. Core Drill Bits

Core drill bits are designed to create circular holes in hard materials such as concrete, stone, and masonry. They are commonly used in construction projects and are available in different sizes and shapes. The core drill bits have a hollow center that allows the user to extract the core of the material they are drilling.

2. Diamond Hole Saw

Diamond hole saws are used to cut holes in materials such as glass, ceramic, and porcelain. They have a circular shape and are available in different diameters. The diamond hole saws work by grinding away the material, leaving a clean and precise hole.

3. Diamond Core Bits

Diamond core bits are similar to core drill bits but are designed to drill larger holes. They are commonly used in construction projects to create holes for pipes, wires, and cables. The diamond core bits have a hollow center that allows the user to extract the core of the material they are drilling.

4. Diamond Burr Bits

Diamond burr bits are used for engraving, carving, and shaping hard materials such as glass, stone, and metal. They are available in different shapes and sizes and can be used with a rotary tool. The diamond burr bits work by grinding away the material, leaving a smooth and precise finish.

Overall, diamond drill bits are a versatile and efficient tool for drilling holes in hard materials. By choosing the right type of diamond drill bit for your project, you can ensure a clean and precise hole every time.

How Diamond Drill Bits Work

As the name suggests, diamond drill bits use diamond particles to cut through hard materials. The diamond particles are embedded in the drill bit’s metal body, which provides the necessary strength and stability to the bit.

Diamond is the hardest naturally occurring material on earth, which gives diamond drill bits their immense cutting power. The diamond particles on the drill bit’s tip grind away at the material, creating a hole. The cutting power of diamond drill bits is unmatched by any other type of drill bit, making them the go-to option for drilling through hard materials.

When using a diamond drill bit, it’s essential to have a power drill with enough speed and torque to handle the bit’s cutting power. A power drill with a variable speed setting is ideal, as it allows you to adjust the drill’s speed to match the material you’re drilling through.

It’s also essential to use the correct drill speed when using a diamond drill bit. Drilling too fast can cause the diamond particles to overheat and become damaged, reducing the bit’s cutting power. On the other hand, drilling too slowly can cause the bit to become clogged with material, reducing its effectiveness.

In summary, diamond drill bits work by using diamond particles to grind away at hard materials, providing unmatched cutting power. To use a diamond drill bit effectively, you need a power drill with enough speed and torque, and you must use the correct drill speed to avoid damaging the bit or reducing its effectiveness.

Using Diamond Drill Bits on Various Materials

https://www.youtube.com/watch?v=SHigFQQjkRY&embed=true

When it comes to drilling through hard materials, diamond drill bits are the perfect tool for the job. They are capable of drilling through materials that other drill bits simply can’t handle, such as granite, glass, stone, ceramic, porcelain, tiles, sea glass, rock, shell, antler, bone, and many other non-wood surfaces.

One of the key advantages of using diamond drill bits is their ability to drill through hard materials without causing damage or cracking. This is particularly important when working with delicate materials such as glass or ceramics. Diamond drill bits are also capable of drilling through thick materials quickly and efficiently.

When drilling through hard materials, it’s important to use the right technique. Start by marking the spot where you want to drill and securing the material in place. Use a slow speed and apply light pressure to the drill bit. It’s important not to apply too much pressure as this can cause the drill bit to overheat and wear out quickly.

When drilling through materials such as glass or ceramic, it’s a good idea to use a lubricant such as water or oil. This will help to keep the drill bit cool and prevent it from overheating. It’s also important to use a diamond drill bit that is the right size for the job. Using a drill bit that is too small or too large can result in damage to the material or the drill bit itself.

In summary, diamond drill bits are an essential tool for anyone working with hard materials such as granite, glass, stone, ceramic, porcelain, tiles, sea glass, rock, shell, antler, bone, and other non-wood surfaces. By using the right technique and the right size drill bit, you can drill through these materials quickly and efficiently without causing damage or cracking.

Cooling and Lubrication in Diamond Drilling

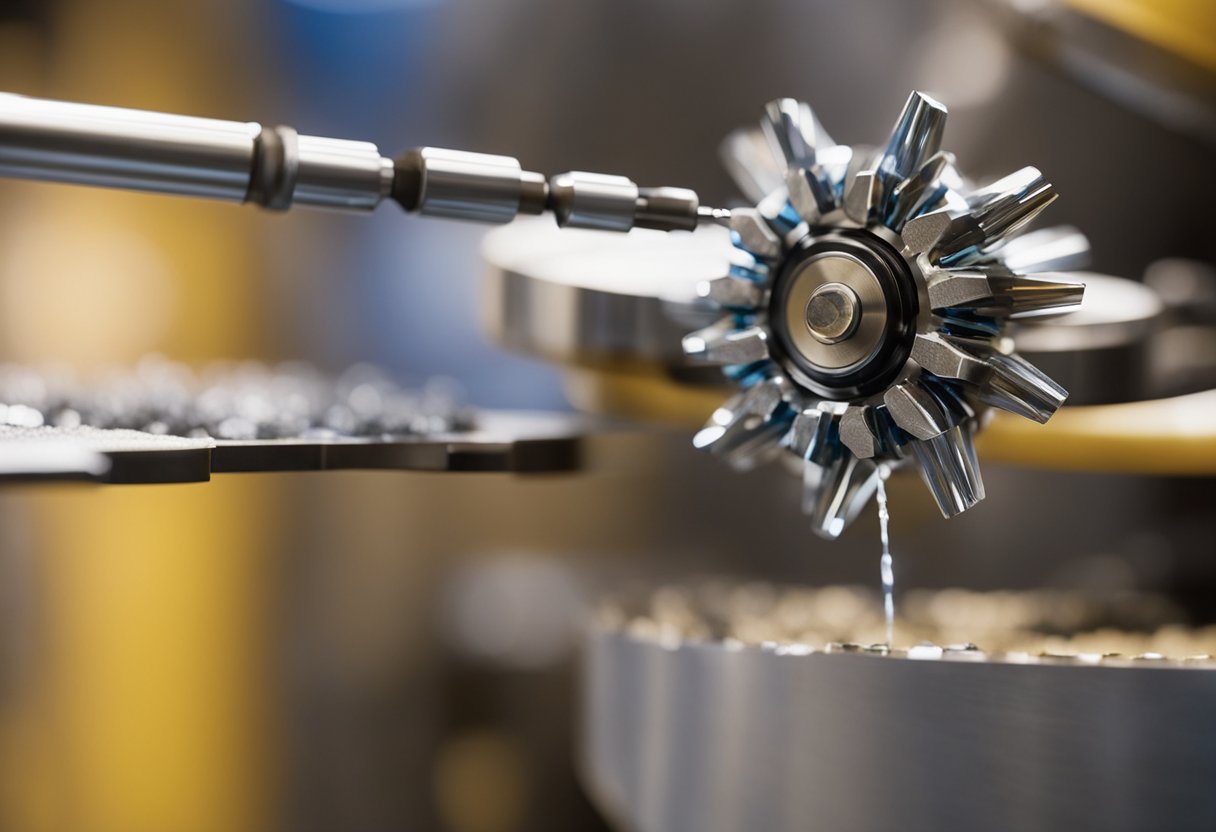

As a diamond drill bit cuts through hard materials, it generates a lot of heat and friction, which can cause the bit to wear out quickly or even break. Therefore, it is essential to use a cooling and lubrication system when drilling with a diamond drill bit to prevent overheating and extend the life of the bit.

There are two main types of cooling and lubrication systems that can be used: water-based and oil-based. Water is the most commonly used coolant and lubricant for diamond drilling because it is inexpensive and readily available. Additionally, water is an effective coolant because it has a high specific heat capacity, which means it can absorb a lot of heat without increasing in temperature. Water also helps to flush away debris and keep the cutting surface clean, which can improve the drilling performance.

When using water as a coolant and lubricant, it is important to ensure that the water is flowing continuously over the cutting surface of the bit. This can be achieved using a water feed system, which delivers a constant stream of water to the drill bit. The water feed system should be adjusted to deliver the correct amount of water, which will depend on the material being drilled and the speed of the drill.

Oil-based lubricants are not recommended for diamond drilling because they can cause the diamond particles on the cutting surface of the bit to become clogged with debris, reducing the drilling performance. Additionally, oil-based lubricants can cause the bit to overheat and wear out quickly.

In summary, using a cooling and lubrication system is essential when drilling with a diamond drill bit. Water is the most commonly used coolant and lubricant because it is inexpensive, effective, and readily available. It is important to ensure that the water is flowing continuously over the cutting surface of the bit and that the water feed system is adjusted to deliver the correct amount of water. Oil-based lubricants should be avoided because they can reduce the drilling performance and cause the bit to overheat and wear out quickly.

Creating Holes with Diamond Drill Bits

https://www.youtube.com/watch?v=ya0m_Sezr1s&embed=true

Diamond drill bits are the perfect tool for creating holes in hard non-wood surfaces such as ceramic, porcelain, glass, stone, marble, and granite. The little pieces of diamond powder embedded in the drill bits provide extra cutting power, making it easier to create precise holes in these materials.

When using diamond drill bits, it is important to use water as a lubricant to prevent overheating and to flush away debris. This will also help to extend the life of the drill bit.

To create a hole with a diamond drill bit, follow these steps:

- Mark the spot where you want to create the hole with a pencil or marker.

- Place the drill bit on the mark and apply gentle pressure.

- Begin drilling at a slow speed, gradually increasing the speed as you go.

- Keep the drill bit perpendicular to the surface to ensure a straight hole.

- Use water as a lubricant to prevent overheating and to flush away debris.

- Continue drilling until you have created the desired depth of the hole.

- Remove the drill bit and clean up any debris left behind.

Diamond drill bits are also useful for creating hollow areas in hard materials. These hollow areas can be used for a variety of purposes, such as creating a space for a sink or faucet in a countertop.

To create a hollow area with a diamond drill bit, follow these steps:

- Mark the outline of the hollow area with a pencil or marker.

- Use a series of smaller diamond drill bits to create a series of holes along the outline of the hollow area.

- Use a larger diamond drill bit to remove the remaining material between the holes.

- Use water as a lubricant to prevent overheating and to flush away debris.

- Continue drilling until you have created the desired depth of the hollow area.

- Remove the drill bit and clean up any debris left behind.

Creating holes and hollow areas with diamond drill bits requires patience and precision, but with the right technique and equipment, it can be done with ease.

Diamond Drilling for Bead Making

https://www.youtube.com/watch?v=oDDKC39fW4w&embed=true

As a bead maker, I know that drilling holes in beads can be a daunting task, especially when working with hard materials like gemstones, glass, and ceramics. That’s where diamond drill bits come in handy. Diamond drill bits are perfect for drilling holes through hard materials, including beads.

When it comes to drilling holes in beads, there are a few things to keep in mind. First, make sure to use the right size drill bit for the job. Using a drill bit that is too small or too large can result in a damaged bead or a hole that is too large or too small.

Second, it’s important to use the right speed and pressure when drilling. Too much pressure can crack the bead, while too little pressure can result in a slow and inefficient drilling process. I recommend using a low speed and applying gentle, consistent pressure to achieve the best results.

Another important factor to consider when drilling beads is the lubricant. Using a lubricant like water or cutting oil can help keep the drill bit cool and prevent it from overheating. It can also help reduce the risk of the bead cracking during the drilling process.

Overall, diamond drill bits are an essential tool for bead makers looking to drill holes in hard materials like gemstones, glass, and ceramics. By using the right size drill bit, applying the right speed and pressure, and using a lubricant, you can achieve clean, precise holes in your beads every time.

Frequently Asked Questions

How are diamond drill bits different from masonry drill bits?

Diamond drill bits are different from masonry drill bits in terms of the material they are designed to drill. While masonry drill bits are designed to drill through materials such as brick, concrete, and stone, diamond drill bits are specifically designed to drill through hard materials such as glass, ceramic, and stone.

What materials can diamond drill bits be used on?

Diamond drill bits can be used on a variety of materials, including glass, ceramic, stone, and even hard metals like stainless steel. They are perfect for drilling holes through hard materials that traditional drill bits cannot penetrate.

What is the best diamond drill bit for stone jewelry?

When it comes to drilling holes in stone jewelry, it’s important to use a diamond drill bit that is specifically designed for the job. Look for diamond drill bits that are designed for use on hard materials like stone and have a small diameter to ensure precision and accuracy.

How do you use a diamond drill bit on glass?

To use a diamond drill bit on glass, you’ll need to first mark the spot where you want to drill the hole. Then, apply a small amount of water to the area to keep the drill bit cool and prevent the glass from cracking. Finally, use a slow and steady drilling motion, applying gentle pressure to the drill bit until the hole is complete.

What is a diamond core drill bit used for?

A diamond core drill bit is used for drilling large diameter holes in hard materials like concrete, brick, and stone. These drill bits are designed to be used with a drill rig and are typically used in construction and engineering applications.

Are diamond drill bits made with real diamonds?

Yes, diamond drill bits are made with real diamonds. The diamonds are typically industrial grade and are embedded in the drill bit using a process called electroplating. This process ensures that the diamonds are securely attached to the drill bit and can withstand the high temperatures and pressures involved in drilling through hard materials.

Hi, I’m Sal Muller of Tooltrip.com. My DIY experience led me to understand essential power tools for home projects. Tooltrip.com guides enthusiasts and professionals in choosing right tools for any job. I provide concise top tool reviews for easier, efficient DIY.