Spray foam and Bondo are two popular materials used in the automotive industry for various applications. Spray foam is used for insulation purposes, while Bondo is used for repairing dents, scratches, and rust spots. When it comes to longevity and durability, it’s important to understand the factors that affect the lifespan of these materials, as well as their application and maintenance.

Understanding Spray Foam and Bondo is essential to determine their effectiveness and longevity. Spray foam is a type of insulation material that expands and hardens after application, providing a seamless and airtight barrier that prevents heat loss and air infiltration. Bondo, on the other hand, is a polyester-based body filler that is used to repair dents, scratches, and rust spots on cars. It is a popular choice because it is easy to use, dries quickly, and can be sanded and painted over.

Key Takeaways

- The longevity and durability of spray foam and Bondo depend on various factors, such as proper installation techniques, environmental conditions, and the specific usage of the materials.

- Spray foam is an effective insulation material that can last for several years, while Bondo is a popular choice for repairing dents, scratches, and rust spots on cars.

- To ensure the longevity of spray foam and Bondo, proper preparation, application, and maintenance are essential.

Understanding Spray Foam and Bondo

https://www.youtube.com/watch?v=tmaWC7ZkVi8&embed=true

As a car owner, it is essential to understand the different materials used for repairing the car’s body. Two common materials used for car body repairs are spray foam and Bondo. Spray foam is a type of insulation material that expands and hardens when sprayed. On the other hand, Bondo is a brand of automotive body filler that is used to repair dents, cracks, and holes in the car’s body.

Spray foam is typically made of polyurethane, a type of plastic that is used in a wide range of applications, including insulation and cushioning. Polyurethane is an excellent insulator, which makes spray foam an effective insulation material. When used in car body repairs, spray foam can help fill gaps and holes in the car’s body, making it more energy-efficient and reducing noise levels.

Bondo, on the other hand, is made of a combination of chemical components, including polyester resin and fiberglass filler. Bondo is available in different forms, including Bondo-Glass and ordinary Bondo filler. Bondo-Glass is a type of Bondo that contains fiberglass strands, making it more durable and resistant to cracking than ordinary Bondo filler.

Both spray foam and Bondo are used to repair dents, cracks, and holes in the car’s body. However, they differ in their application and effectiveness. Spray foam is more effective at filling gaps and holes, while Bondo is more effective at repairing dents and cracks.

In summary, spray foam and Bondo are two common materials used for car body repairs. Spray foam is typically made of polyurethane and is an excellent insulator, while Bondo is made of a combination of chemical components, including polyester resin and fiberglass filler. Understanding the differences between these materials can help you make informed decisions when repairing your car’s body.

Longevity and Durability

https://www.youtube.com/watch?v=wib2KjHiVxY&embed=true

As someone who has worked with spray foam and Bondo extensively, I can attest to their durability and longevity. Spray foam and Bondo are both popular materials used in automotive repairs, construction, and insulation. When it comes to lifespan, durability, and maintenance, there are a few things to keep in mind.

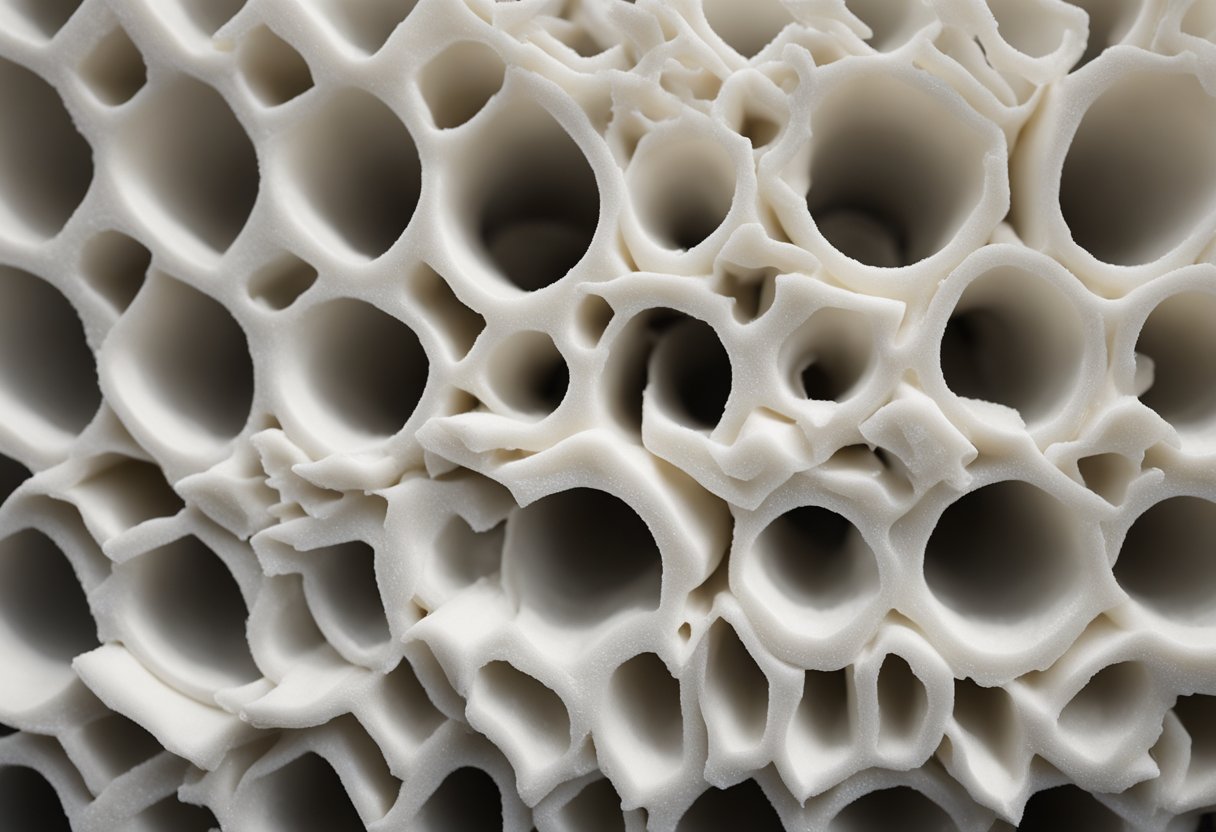

Spray foam insulation can last for up to 80-100 years, making it a permanent solution for insulation needs. Closed-cell spray foam, in particular, is known for its durability and ability to withstand wear and tear over time. This type of foam has a higher density than open-cell foam, making it more resistant to moisture, mold, and pests. In addition, closed-cell spray foam has a higher R-value, which means it provides better insulation than open-cell foam.

In terms of Bondo, the lifespan and durability depend on a few factors, including the severity of the damage, the quality of the repair, and the conditions the vehicle is exposed to. Generally, Bondo can last for several years if applied correctly and maintained properly. However, it is not a permanent solution and may need to be reapplied over time.

Regular maintenance is key to extending the lifespan of both spray foam and Bondo. For example, checking for signs of wear and tear, such as cracks or gaps, and repairing them promptly can prevent further damage and prolong the life of the materials. In addition, proper installation techniques and environmental conditions can also impact the longevity of spray foam and Bondo.

Overall, spray foam and Bondo are both durable materials that can provide long-lasting solutions for insulation and repairs. With proper maintenance and care, these materials can last for several years, making them a cost-effective option in the long run.

Factors Affecting Lifespan

https://www.youtube.com/watch?v=uJV9vgkNBHY&embed=true

As with any material, the lifespan of spray foam and Bondo can be influenced by a variety of factors. Here are some of the most important factors that can affect the longevity of these materials:

Surface Preparation

One of the most critical factors affecting the lifespan of spray foam and Bondo is the quality of the surface preparation. Proper surface preparation ensures that the materials adhere correctly to the surface, which is essential for their longevity. Any contaminants or moisture on the surface can cause the materials to fail prematurely.

Moisture Infiltration

Moisture infiltration can have a significant impact on the lifespan of spray foam and Bondo. Moisture can cause the materials to deteriorate over time, leading to cracks and other damage. Proper insulation and sealing can help prevent moisture infiltration and prolong the lifespan of these materials.

Environmental Conditions

The environmental conditions in which spray foam and Bondo are used can also affect their lifespan. Extreme temperatures, UV radiation, and other environmental factors can cause the materials to degrade more quickly. It’s essential to choose materials that are appropriate for the specific environmental conditions in which they will be used.

Climate

Climate is another critical factor that can affect the lifespan of spray foam and Bondo. In areas with high humidity or frequent temperature fluctuations, these materials may not last as long as they would in more stable conditions. It’s important to choose materials that are appropriate for the climate in which they will be used.

Moisture Exposure

Moisture exposure can also have a significant impact on the lifespan of spray foam and Bondo. If these materials are exposed to moisture for extended periods, they can deteriorate more quickly. Proper insulation and sealing can help prevent moisture exposure and prolong the lifespan of these materials.

In summary, the lifespan of spray foam and Bondo can be influenced by a variety of factors, including surface preparation, moisture infiltration, environmental conditions, climate, and moisture exposure. By taking these factors into consideration, it’s possible to choose materials that will last as long as possible and provide the best value for your investment.

Application and Maintenance

As someone who has worked with spray foam and Bondo, I can attest to the fact that the longevity of these materials depends heavily on proper application and maintenance. If you want your repairs to last, you need to follow the manufacturer’s instructions closely and take good care of your vehicle.

First and foremost, preparation is key. Before applying spray foam or Bondo, you need to thoroughly clean and dry the area you plan to repair. Any dirt, grease, or moisture can compromise the adhesion of the materials and cause them to fail prematurely.

Once the area is clean, you can begin applying the spray foam or Bondo. When using Bondo as a body filler, it’s important to apply it in thin layers and sand between each layer to ensure a smooth, even finish. If you’re using spray foam to insulate voids in your car, be sure to apply it evenly and allow it to cure completely before proceeding with any additional repairs.

After the spray foam or Bondo has been applied, it’s important to prime and paint the area to protect it from further damage. Proper sanding and preparation of the surface is crucial for achieving a professional-looking finish that will last.

Regular maintenance is also important for ensuring the longevity of your repairs. Be sure to wash your car regularly and avoid exposing it to extreme temperatures or harsh chemicals that can cause the materials to deteriorate.

In conclusion, spray foam and Bondo can provide long-lasting durability for various applications, but only if they are applied properly and maintained regularly. By taking the time to prepare the area, apply the materials correctly, and care for your vehicle, you can ensure that your repairs will last for years to come.

Insulation Properties and Benefits

As a professional insulation contractor, I have seen the benefits of insulation firsthand. Insulation helps to maintain a comfortable temperature in your home, reduces energy costs, and can even improve soundproofing. When it comes to insulation types, spray foam insulation is one of the most effective options available.

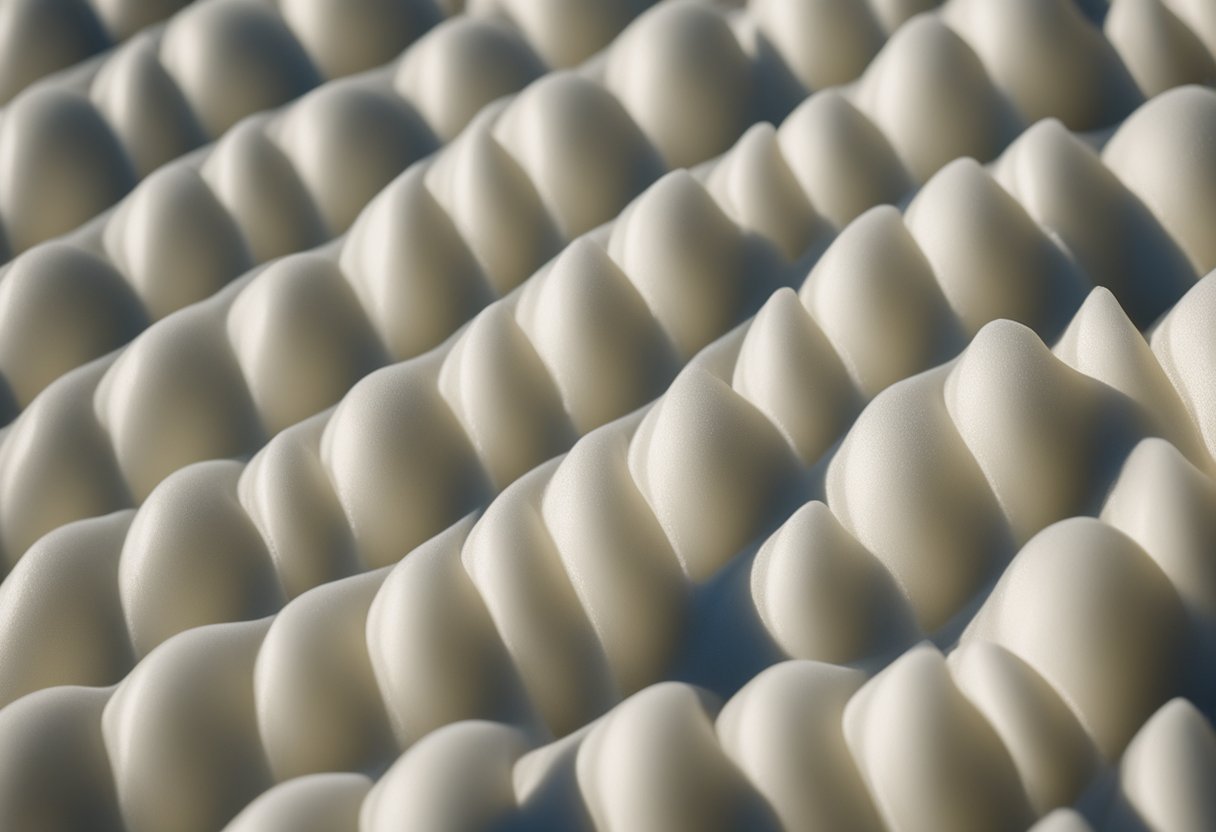

Spray foam insulation is a type of insulation that is applied as a liquid and expands into a foam. There are two types of spray foam insulation: closed-cell spray foam and open-cell spray foam. Closed-cell spray foam has a higher R-value and is more durable than open-cell foam. It is also better at preventing air leaks and is commonly used in crawl spaces and attics. Open-cell foam, on the other hand, is less expensive and provides good insulation for 10-20 years if protected from moisture.

One of the key benefits of spray foam insulation is its ability to reduce energy costs. By preventing air leaks, spray foam insulation can help keep your home at a consistent temperature, reducing the need for heating and cooling. This can result in significant energy savings over time.

In addition to energy savings, spray foam insulation can also improve soundproofing. The foam’s ability to expand and fill gaps can help reduce noise transmission between rooms. This is especially useful for homes located near busy streets or other noisy areas.

While spray foam insulation is a great option, it is important to note that it is not the only type of insulation available. Fiberglass insulation, cellulose insulation, and mineral wool insulation are also commonly used. Each type has its own benefits and drawbacks, so it is important to consult with a professional insulation contractor to determine the best option for your home.

Overall, spray foam insulation is a durable and effective option for homeowners looking to improve energy efficiency and soundproofing in their homes. With proper installation and maintenance, closed-cell spray foam can realistically last over 50 years, while open-cell foam provides good insulation for 10-20 years if protected from moisture.

Usage in Different Areas

When it comes to using spray foam and Bondo, there are a variety of areas where these materials can be applied. In this section, I will discuss some of the most common areas where these materials are used and how long they can last.

Flooring

Spray foam insulation can be used to insulate floors, providing a barrier between the cold ground and the interior of a building. Closed-cell spray foam is an excellent option for this application, as it is rigid and can withstand the weight of foot traffic. Additionally, closed-cell spray foam is resistant to water and can help prevent moisture from seeping up through the floor.

Bondo can also be used to repair damaged floors. However, it is important to note that Bondo is not a long-term solution for flooring. Bondo is a filler, not a structural material, and it can crack and break down over time. For a more durable solution, it is recommended to replace damaged flooring rather than repair it with Bondo.

Ceiling

Spray foam insulation can also be used to insulate ceilings, providing a barrier between the interior of a building and the outside elements. Closed-cell spray foam is a good option for this application, as it can help prevent air leakage and provide a high R-value. However, it is important to note that spray foam insulation is not a fire barrier, and additional fire protection measures may be necessary.

Bondo is not typically used for ceiling repairs, as it is not a structural material and may not provide adequate support. Instead, drywall or other structural materials are typically used for ceiling repairs.

Door Panels

Bondo can be used to repair damaged door panels. However, it is important to note that Bondo is not a long-term solution for door panel repairs. Bondo can crack and break down over time, especially if the door panel is exposed to the elements. For a more durable solution, it is recommended to replace damaged door panels rather than repair them with Bondo.

Commercial Buildings

Spray foam insulation is commonly used in commercial buildings to provide insulation and air sealing. Closed-cell spray foam is an excellent option for this application, as it can help prevent air leakage and provide a high R-value. Additionally, closed-cell spray foam is resistant to water and can help prevent moisture from seeping into the building.

Bondo is not typically used in commercial building applications, as it is not a structural material and may not provide adequate support.

Welding

Bondo is not typically used in welding applications, as it is not a heat-resistant material and may break down or melt when exposed to high temperatures. Welding requires specialized materials and techniques, and it is important to use the appropriate materials for welding repairs.

Voids

Spray foam insulation can also be used to fill voids, such as gaps between walls or around pipes. Closed-cell spray foam is a good option for this application, as it can expand to fill voids and provide a barrier against air leakage and moisture.

Bondo can also be used to fill voids, but it is important to note that Bondo is not a long-term solution for void filling. Bondo can crack and break down over time, especially if it is exposed to the elements. For a more durable solution, it is recommended to use a structural material to fill voids.

Preparation and Application Process

https://www.youtube.com/watch?v=kZuYvaMZp2s&embed=true

When it comes to using spray foam and Bondo, proper preparation and application are crucial for achieving long-lasting results.

Before applying either product, it is important to clean the surface thoroughly and remove any rust or debris. For metal surfaces, it is recommended to use a rust converter to prevent future rusting.

Once the surface is clean and dry, it is time to prepare the Bondo filler or spray foam mixture. The mixture ratio for both products is critical for achieving the desired consistency and strength. Always follow the manufacturer’s instructions for the correct ratio.

When mixing Bondo filler, it is essential to add the hardener in the correct proportion, as this will determine the curing time. A filler that cures too quickly or too slowly can cause problems with adhesion and durability.

After the mixture is prepared, apply the Bondo or spray foam to the surface using a spreader or spray gun, respectively. It is important to apply the product in thin layers, building up the thickness gradually to avoid bumps and imperfections.

Once the product has cured, it is time to sand the surface using sandpaper. This step is important for achieving a smooth and even surface before painting. Be sure to use the correct grit of sandpaper for the job, as using too coarse of a grit can damage the surface.

Overall, the preparation and application process for spray foam and Bondo requires attention to detail and careful consideration of the mixture ratio, thickness, and sanding. By following these steps, you can ensure a durable and long-lasting repair for your vehicle.

Frequently Asked Questions

What is the lifespan of spray foam and bondo in car body repair?

The lifespan of spray foam and bondo in car body repair depends on several factors such as the quality of installation, environmental conditions, and the specific usage of the materials. According to AutoGuruz, spray foam and bondo typically last for several years, providing long-lasting durability for various applications.

Does spray foam prevent rust in car body repair?

Spray foam does not prevent rust in car body repair. However, it can help prevent moisture buildup and reduce the risk of rust forming in the first place. According to Cherish Your Car, the primary use of spray foam is to insulate the voids on a car to provide better temperature control and shield outside noises.

Can expanding foam be used as a body filler in car repair?

Expanding foam should not be used as a body filler in car repair. While it may seem like an easy solution, expanding foam is not designed for use as a body filler and can cause more problems than it solves. Instead, use a high-quality body filler such as bondo for car repairs.

How long does expanding foam last in car body repair?

The lifespan of expanding foam in car body repair depends on several factors such as the quality of installation, environmental conditions, and the specific usage of the materials. According to Phase Insulation, spray foam insulation can last for up to 80 years or more, but this may vary depending on the type of foam used and the conditions it is exposed to.

Is it safe to sleep in a house after spray foam insulation?

It is generally safe to sleep in a house after spray foam insulation has been installed. However, it is recommended to wait at least 24 hours after installation before re-entering the area to allow the foam to fully cure and any fumes to dissipate. According to Storables, properly installed and maintained foam insulation can last for 20 to 30 years or even longer.

What are the benefits of using spray foam in car body repair?

Spray foam has several benefits when used in car body repair. It can help insulate the car, reduce noise, and improve temperature control. It can also help prevent moisture buildup and reduce the risk of rust forming in the first place. Additionally, spray foam can be used to fill voids and gaps in the car body, providing a smooth surface for painting and finishing.

Hi, I’m Sal Muller of Tooltrip.com. My DIY experience led me to understand essential power tools for home projects. Tooltrip.com guides enthusiasts and professionals in choosing right tools for any job. I provide concise top tool reviews for easier, efficient DIY.