Self-etching primer is a type of coating that is applied to metal surfaces before painting. It is designed to improve paint adhesion and prevent rust formation. But how does self-etching primer work, and what makes it different from other types of primers?

Self-etching primer works by chemically bonding with the metal surface, creating a strong and durable foundation for the paint to adhere to. Unlike traditional primers, which rely on mechanical adhesion, self-etching primers use a combination of acid and resin to create a chemical bond. This bond is stronger and more reliable than a simple mechanical bond, which can be weakened by moisture, temperature changes, and other factors.

To use self-etching primer, the metal surface must be clean, dry, and free of any rust or other contaminants. The primer is then applied in a thin, even layer, using a brush, roller, or spray gun. Once the primer has dried, it can be sanded and painted over with any type of paint. Self-etching primer is particularly useful for automotive applications, where it can provide long-lasting protection against rust and other types of corrosion.

Key Takeaways

- Self-etching primer chemically bonds with metal surfaces to create a strong and durable foundation for paint.

- This type of primer is particularly useful for automotive applications, where it can provide long-lasting protection against rust and other types of corrosion.

- To use self-etching primer, the metal surface must be clean, dry, and free of any rust or other contaminants.

Understanding Self-Etching Primer

https://www.youtube.com/watch?v=e2lkivgV26o&embed=true

As a professional painter, I have used various types of primers to prepare surfaces for painting. Self-etching primer is a type of primer that is commonly used in automotive, household, and industrial projects. It is a specialized primer that is designed to bond with metal, aluminum, and fiberglass surfaces.

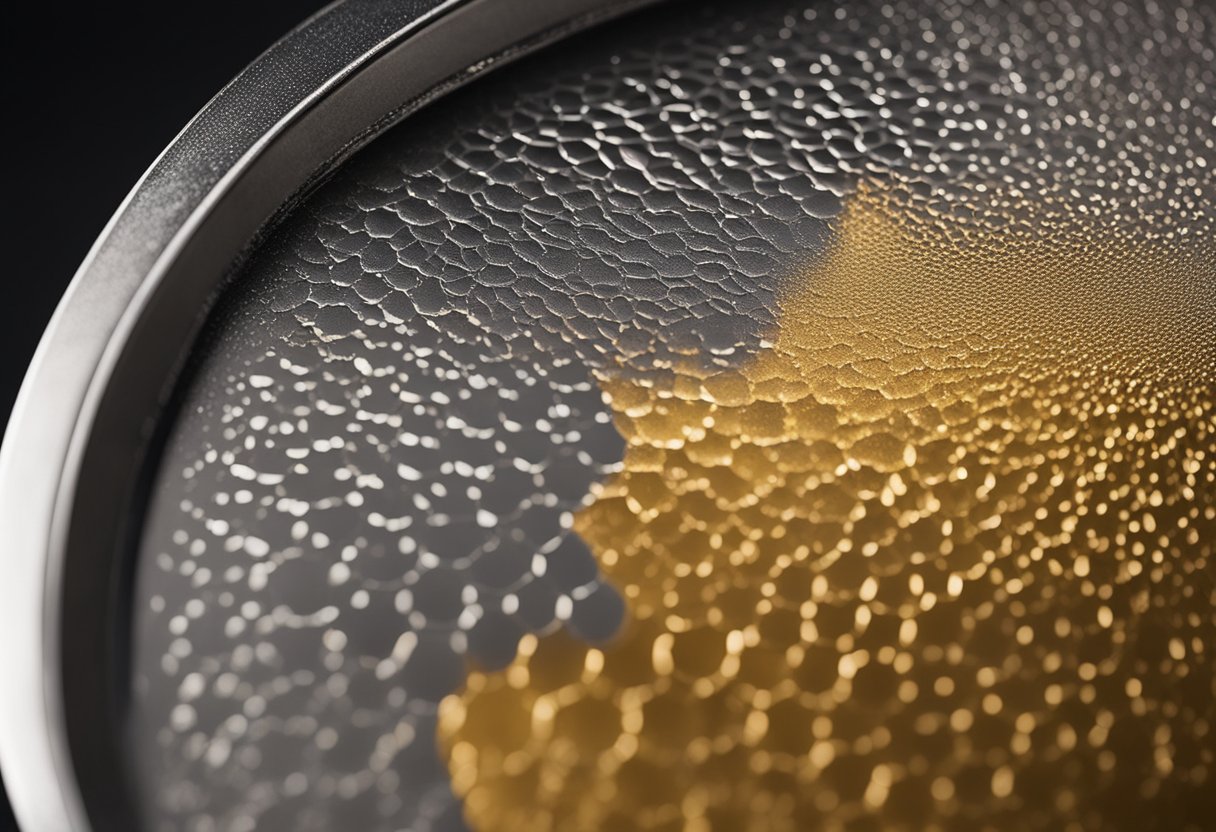

Self-etching primer works by etching the surface of the metal to create a rough texture that the primer can bond with. The primer contains an acidic chemical that reacts with the metal surface and creates a chemical bond that is much stronger than a mechanical bond. The result is a surface that is better prepared for painting and provides better adhesion for the topcoat.

One of the advantages of self-etching primer is that it can be used as a primary undercoat. It provides a uniform surface that the paint can adhere to, which can help to improve the overall appearance of the final paint job.

When using self-etching primer, it is important to follow the manufacturer’s instructions carefully. The surface must be clean and free of any contaminants such as oil, grease, or rust. The primer should be applied in thin, even coats and allowed to dry completely before applying the topcoat.

It is worth noting that self-etching primer is not suitable for all surfaces. It is designed for use on metal, aluminum, and fiberglass surfaces only. For other surfaces, such as wood or plastic, other types of primers should be used.

In summary, self-etching primer is a specialized type of primer that is designed to bond with metal, aluminum, and fiberglass surfaces. It works by etching the surface of the metal to create a rough texture that the primer can bond with. It provides a uniform surface that the paint can adhere to, which can help to improve the overall appearance of the final paint job.

Components and Properties

Self-etching primer is a type of primer that is specifically designed to be used on metal surfaces. It is made up of several components, including acid, synthetic resin, solvent, pigment, and additives. One of the key components of self-etching primer is phosphoric acid, which is responsible for etching the metal surface and creating a strong bond between the primer and the metal.

Zinc is another important component of self-etching primer. Zinc particles are added to the primer to help prevent rust from forming on the metal surface. This is important because rust can weaken the metal and cause it to deteriorate over time. By using self-etching primer, you can help to protect the metal surface and extend its lifespan.

In addition to these components, self-etching primer also contains a synthetic resin that helps to bind the primer to the metal surface. This resin is designed to be durable and long-lasting, ensuring that the primer remains in place and provides a strong base for the paint to adhere to.

The solvent in self-etching primer is responsible for thinning the primer and making it easier to apply. This allows the primer to be spread evenly over the metal surface, ensuring that it provides complete coverage and a uniform surface for the paint to adhere to.

Overall, self-etching primer is a powerful and effective primer that is designed to provide excellent adhesion to metal surfaces. Its unique combination of components, including phosphoric acid, zinc, synthetic resin, solvent, and pigment, make it an ideal choice for anyone looking to protect and enhance the appearance of their metal surfaces.

Preparation and Application

https://www.youtube.com/watch?v=cNn9OY-_07k&embed=true

Before applying self-etching primer, it is important to prepare the surface properly. The surface should be clean and free of any dirt, grease, or oil. Sanding the surface with sandpaper is necessary to remove any rust, old paint, or debris. The grit of the sandpaper should be chosen based on the condition of the surface. A coarse grit can be used for rough surfaces, while a fine grit is more suitable for smoother surfaces.

When sanding the surface, it is important to use a back-and-forth motion to ensure that the surface is even and smooth. After sanding, wipe the surface clean with a cloth to remove any dust or debris. Mineral spirits can be used to clean the surface further if needed.

Once the surface is clean and smooth, the self-etching primer can be applied. It is important to apply thin coats of primer, as thick coats can lead to drips and uneven coverage. Shake the can well before use, and use a mixing ball if necessary.

When applying the primer, it is important to follow the manufacturer’s instructions carefully. Some primers may require multiple coats, with dry sanding between each coat. Dry sanding can be done with a fine grit sandpaper to ensure that the surface is smooth and even.

Overall, proper surface preparation and application techniques are key to achieving a successful outcome with self-etching primer.

Benefits and Comparison

Self-etching primer is a popular choice for those looking to paint metal surfaces. It offers several benefits over traditional primers, including improved adhesion, rust and corrosion protection, and a uniform surface for the paint to adhere to.

One of the main advantages of self-etching primer is its ability to improve adhesion. The primer contains an acid that etches the surface of the metal, creating a rough surface that the paint can bond to. This rough surface helps the paint adhere better, resulting in a more durable finish.

Another benefit of self-etching primer is its ability to prevent rust and corrosion. The primer contains zinc phosphate pigmentation, which helps to prevent rust from forming on the metal surface. This is especially important in areas where the metal is exposed to moisture or other corrosive elements.

When compared to traditional primers, self-etching primer offers superior corrosion protection. Traditional primers do not contain the same level of corrosion resistance as self-etching primer, making them less effective at preventing rust and other forms of corrosion.

In addition to improved adhesion and corrosion protection, self-etching primer also offers a uniform surface for the paint to adhere to. This helps to improve the overall appearance of the final paint job, resulting in a smoother, more even finish.

Overall, self-etching primer offers several benefits over traditional primers. It provides improved adhesion, rust and corrosion protection, and a uniform surface for the paint to adhere to. When compared to traditional primers, self-etching primer offers superior corrosion protection, making it an ideal choice for those looking to paint metal surfaces.

Types of Surfaces and Compatibility

https://www.youtube.com/watch?v=5kt7bk8gnpQ&embed=true

When it comes to self-etching primer, it is important to understand its compatibility with different types of surfaces. This type of primer is designed to be used on bare metal surfaces, including aluminum, brass, steel, and more. It can also be used on porous surfaces such as drywall, brick, concrete, and masonry.

However, it is important to note that self-etching primer may not be suitable for all surfaces. For instance, it may not be effective on wood or plastic surfaces. In such cases, it is recommended to use a different type of primer that is specifically designed for those surfaces.

If you are working on an automotive project, self-etching primer may be a good choice for you. It is commonly used in the automotive industry to provide a strong foundation for paint adhesion and to enhance corrosion resistance. However, it is important to ensure that the self-etching primer you choose is compatible with the specific type of metal used in your vehicle.

In addition to its compatibility with different surfaces, self-etching primer is also available in different formulations. For instance, there are self-etching primers that are specifically designed for use on fiberglass surfaces. These types of primers are commonly used in boat building and repair projects.

Overall, when choosing a self-etching primer, it is important to consider the type of surface you will be working with and ensure that the primer is compatible with that surface. This will help to ensure that you achieve the best possible results for your project.

Use Cases and Techniques

As an automotive professional, I have found that self-etching primer is an excellent choice for preparing bare metal, aluminum, and fiberglass surfaces for painting. It provides maximum bonding and creates a rust-preventive coating that ensures that the paint adheres well to the surface.

When using self-etching primer, it is important to follow the manufacturer’s instructions carefully. Typically, the surface must be cleaned thoroughly and free of any rust, dust, or debris. Once cleaned, the self-etching primer can be applied using a spray gun, roller, or brush, depending on the size and shape of the surface being painted.

One of the benefits of using self-etching primer is that it both etches and primes the surface in one step. This means that fewer coats of primer paint are required, saving time and money. Additionally, self-etching primer is oil-based, which makes it more durable and resistant to corrosion than water-based primers.

For best results, it is recommended to use a high-build primer on top of the self-etching primer. This will help to create a smooth surface for the top coat of paint to adhere to.

When applying self-etching primer, it is important to work in a well-ventilated area and to wear protective gear, such as gloves and a respirator. It is also important to allow the primer to dry completely before applying the top coat of paint.

In a professional paint shop, self-etching primer is often used on automotive parts, such as bumpers, to ensure that the paint adheres well and lasts a long time. However, it can also be used for other applications, such as on metal furniture or outdoor equipment.

Overall, self-etching primer is an excellent choice for anyone looking to create a durable and long-lasting paint job. By following the manufacturer’s instructions and using the proper techniques, it is possible to achieve a professional-looking finish that will last for years to come.

Safety and Environmental Considerations

When working with self-etching primer, it is important to take certain safety and environmental considerations into account. Here are some key points to keep in mind:

-

Ventilation: Self-etching primer contains chemicals that can be harmful if inhaled, so it is important to work in a well-ventilated area. If you are working indoors, make sure to open windows and doors, and consider using a fan to help circulate the air.

-

Protective gear: It is also important to wear protective gear when working with self-etching primer. This includes gloves, eye protection, and a respirator mask. You should also wear long sleeves and pants to protect your skin.

-

Spills and clean-up: If you spill self-etching primer, it is important to clean it up immediately. Use a cloth or paper towel to absorb as much of the primer as possible, and then dispose of it properly. Do not pour it down the drain or throw it in the trash. Check with your local waste disposal facility for proper disposal guidelines.

-

Environmental impact: Self-etching primer can have a negative impact on the environment if not disposed of properly. Make sure to follow all local regulations for hazardous waste disposal.

-

Cost: Self-etching primer can be more expensive than traditional primers, so it is important to factor in the cost when planning your project.

-

DIY vs. professional: While self-etching primer can be used for DIY projects, it is important to note that it requires a certain level of skill and experience to apply properly. If you are not confident in your abilities, it may be best to hire a professional.

-

Sealing and moisture: Self-etching primer can help to seal the surface of the metal and prevent moisture from getting in, which can help to prevent rust from forming.

-

Topcoat finish: Self-etching primer is designed to be used as a base coat, and it is important to apply a topcoat finish over it to protect the surface and ensure longevity.

Overall, self-etching primer can be a great option for those looking to paint metal surfaces. However, it is important to take the necessary safety and environmental precautions when working with it.

Frequently Asked Questions

https://www.youtube.com/watch?v=MDXwdTC1CzM&embed=true

How long do you leave etch primer on before painting?

The recommended time for leaving self etching primer on before painting varies by manufacturer and product. However, most self etching primers require a waiting time of 10-15 minutes before applying paint. It is essential to follow the manufacturer’s instructions for the best results.

Can you paint directly over self etching primer?

Yes, you can paint directly over self etching primer. In fact, self etching primer is specifically designed to be used as a base coat for paint. It provides a smooth and durable surface for the paint to adhere to. However, it is crucial to wait for the recommended time before applying paint.

Do you have to sand after using self etching primer?

Yes, sanding after using self etching primer is recommended. Sanding helps to create a smoother surface for the paint to adhere to. It also helps to remove any imperfections or rough spots on the surface. However, it is crucial to follow the manufacturer’s instructions for sanding and wait for the recommended time before sanding.

What is the purpose of self etching primer?

The purpose of self etching primer is to prepare bare metal, aluminum, and fiberglass surfaces for painting. It creates a rust-preventive coating, providing maximum bonding. Self etching primer also helps to create a smooth and durable surface for the paint to adhere to.

How does self etching primer adhere to metal?

Self etching primer adheres to metal by chemically bonding with the surface. It contains an acid that etches the metal, creating a rough surface for the primer to adhere to. The rough surface created by the etching process provides a mechanical bond for the primer to adhere to. This bond helps to prevent the primer from peeling or flaking off.

Are there any safety precautions to take when using self etching primer?

Yes, there are safety precautions to take when using self etching primer. It is essential to wear protective clothing, gloves, and eyewear to avoid contact with the skin or eyes. It is also crucial to use self etching primer in a well-ventilated area to avoid inhaling the fumes. It is recommended to read the manufacturer’s instructions and follow the safety precautions listed.

Hi, I’m Sal Muller of Tooltrip.com. My DIY experience led me to understand essential power tools for home projects. Tooltrip.com guides enthusiasts and professionals in choosing right tools for any job. I provide concise top tool reviews for easier, efficient DIY.