Spline sockets are a type of socket wrench that is used to tighten or loosen fasteners with splines. They are designed to fit over the spline, which is a series of ridges or teeth on the fastener, and provide a secure grip that allows you to apply torque without slipping or damaging the fastener. Spline sockets come in a variety of sizes and types, and are used in a wide range of industries and applications.

Spline sockets are an essential tool for anyone who works with fasteners, particularly those with splines. They are designed to provide a secure, non-slip grip on the fastener, allowing you to apply torque without slipping or damaging the fastener. This makes them ideal for use in a wide range of applications, from automotive repair and maintenance to industrial manufacturing and construction.

There are many different types of spline sockets available, each designed for a specific type of fastener or application. Some of the most common types include standard spline sockets, double hex spline sockets, and triple square spline sockets. Each type has its own unique features and benefits, and is designed to provide a secure, non-slip grip that allows you to apply torque without slipping or damaging the fastener.

Key Takeaways on Spline Sockets

- Spline sockets are designed to fit over the spline on a fastener, providing a secure, non-slip grip that allows you to apply torque without slipping or damaging the fastener.

- There are many different types of spline sockets available, each designed for a specific type of fastener or application.

- Spline sockets are an essential tool for anyone who works with fasteners, particularly those with splines, and are used in a wide range of industries and applications.

Understanding Spline Sockets

As a professional mechanic, I have come across various types of sockets that are used to loosen or tighten fasteners. One of the most useful sockets I have found is the spline socket.

A spline socket is a specialized socket designed to fit onto spline-shaped fasteners such as bolts, screws, or nuts. The spline shape resembles a series of teeth or ridges that match up with the corresponding splines on the fastener. This design provides a secure and snug connection between the socket and the fastener, which makes it less likely to slip or round off the corners of the nut.

One of the benefits of using a spline socket is that it can handle high torque applications without damaging the corners of the nut. The larger contact area of the spline socket allows for higher torquing without causing damage. This makes it a great tool to have in your toolbox if you work with fasteners that require high torque.

Another advantage of using a spline socket is that it offers higher strength in a more compact profile. The spline design distributes the force evenly over the fastener, which reduces the risk of stripping or damaging the fastener. This makes it a reliable tool to use when working with high-stress fasteners.

Overall, spline sockets are quite useful and offer several advantages over conventional sockets. If you work with fasteners that require high torque or high-stress applications, I highly recommend adding a spline socket to your toolbox.

Types of Spline Sockets

As we’ve already established, spline sockets are designed to fit onto spline-shaped fasteners. They’re available in a range of different types, each with its own unique features and benefits. Here are some of the most common types of spline sockets:

12 Point Spline Socket

A 12 point spline socket is a type of socket that has 12 points of contact on the fastener. This means that it provides a more secure grip than a 6 point or square socket. It’s often used for heavy-duty applications where high torque is required.

6 Point Spline Socket

A 6 point spline socket is a type of socket that has 6 points of contact on the fastener. It’s often used for applications where a lower torque is required, as it provides a less secure grip than a 12 point spline socket.

Square Spline Socket

A square spline socket is a type of socket that has a square-shaped opening. It’s often used for applications where a square-shaped fastener is used.

Hex Socket

A hex socket is a type of socket that has a hexagonal-shaped opening. It’s often used for applications where a hexagonal-shaped fastener is used. It’s a versatile socket that can be used for a wide range of applications.

Torx Socket

A torx socket is a type of socket that has a star-shaped opening. It’s often used for applications where a torx-shaped fastener is used. It provides a more secure grip than a hex socket, which can be useful for applications where high torque is required.

Clutch Socket

A clutch socket is a type of socket that has a circular-shaped opening with two flat sides. It’s often used for applications where a circular-shaped fastener with two flat sides is used.

Oval Socket

An oval socket is a type of socket that has an oval-shaped opening. It’s often used for applications where an oval-shaped fastener is used.

Cross Socket

A cross socket is a type of socket that has a cross-shaped opening. It’s often used for applications where a cross-shaped fastener is used.

Each of these types of spline sockets has its own unique features and benefits. When choosing a spline socket, it’s important to consider the type of fastener you’ll be working with and the amount of torque you’ll need to apply.

Manufacturing Process

I have researched and found that spline sockets are made using a variety of manufacturing processes. The most common way to manufacture spline sockets is by milling. Milling is a process that uses rotary cutters to remove material from a workpiece. The process is highly accurate and can produce complex shapes with high precision.

Another method used to manufacture spline sockets is rolling. Rolling is a process that involves passing a metal bar through a set of rollers that shape the bar into the required shape. This process is commonly used to produce splines on shafts and other components.

Grinding is also used to manufacture spline sockets. Grinding is a process that involves removing material from a workpiece using a grinding wheel. This process is used to produce high-precision components with a smooth surface finish.

Extrusion is another method used to manufacture spline sockets. Extrusion involves forcing a metal bar through a die to produce a specific shape. This process is commonly used to produce long, continuous shapes such as tubes or bars.

Spline sockets are usually made from steel, which is a strong and durable material. Steel is an alloy of iron and carbon, and it is commonly used in manufacturing due to its strength and toughness.

In conclusion, spline sockets can be manufactured using a variety of processes, including milling, rolling, grinding, and extrusion. Steel is the most commonly used material for manufacturing spline sockets due to its strength and durability.

Compatibility and Usage

When it comes to compatibility, spline sockets are designed to fit onto spline-shaped fasteners such as bolts, screws, or nuts. The spline shape resembles a series of teeth or ridges that match up with the corresponding splines on the fastener. Spline sockets tend to have a larger contact area that allows higher torquing without damaging the corners of the nut. They are quite useful, and it’s nice to have one in your toolbox.

Spline sockets can be used with both spline drive and square drives. They can also be used with keyway, radial, and axial drives. However, it is important to note that spline sockets are not suitable for use with regular hex heads, but they will work on regular hex heads, but not as well as a normal 6 or 12 point socket. They are sometimes marketed as “universal fit”, but you’re best off avoiding them unless you actually need them.

It is important to choose the right size and type of spline socket for the job. Using the wrong size or type of socket can result in damage to the fastener or the tool, or even injury to the user. Always check the manufacturer’s specifications for the tool and the fastener to ensure compatibility.

In summary, spline sockets are specialized sockets designed to fit onto spline-shaped fasteners. They can be used with both spline drive and square drives, as well as keyway, radial, and axial drives. It is important to choose the right size and type of spline socket for the job to ensure compatibility and prevent damage or injury.

Spline Sockets in Various Industries

As a tool that can tighten and loosen both splines and conventional fasteners, spline sockets have become an indispensable tool in various industries. Here are some examples of how spline sockets are used in different fields:

Military

Spline sockets are commonly used in the military to maintain and repair military vehicles and equipment. The durability and strength of spline sockets make them ideal for heavy-duty applications. Spline sockets are also used in the maintenance of weapons and ammunition, where precision and accuracy are crucial.

Commercial Aircraft

Commercial aircraft are assembled using a wide range of fasteners, including spline fasteners. Spline sockets allow for easy and efficient installation and removal of these fasteners, reducing maintenance time and costs. Spline sockets are also used in the maintenance and repair of aircraft engines, where precision and accuracy are essential.

Aerospace

Spline sockets are used in the aerospace industry for assembly and maintenance of spacecraft, satellites, and other aerospace vehicles. The precision and accuracy of spline sockets ensure that fasteners are tightened to the correct torque specification, reducing the risk of failure and improving safety.

In conclusion, spline sockets are a versatile tool that is used in various industries, including military, commercial aircraft, and aerospace. Their strength, durability, and precision make them an indispensable tool in these fields.

Metric vs SAE Spline Sockets

When it comes to choosing between metric and SAE spline sockets, it all depends on the type of fastener you are working with. If you are working on a foreign car, chances are that you will need metric spline sockets. On the other hand, if you are working on an American-made car, you will need SAE spline sockets.

Metric spline sockets are measured in millimeters and are designed to fit on metric fasteners. They are commonly used on foreign cars and machinery. In contrast, SAE spline sockets are measured in inches and are designed to fit on SAE fasteners. They are commonly used on American-made cars and machinery.

It is important to note that you should always use the correct size socket for the fastener you are working with. Using the wrong size socket can damage the fastener and make it difficult or impossible to remove.

When it comes to choosing between metric and SAE spline sockets, it is important to have both sets on hand. This will ensure that you have the right size socket for any job that comes your way.

In summary, the choice between metric and SAE spline sockets depends on the type of fastener you are working with. Always use the correct size socket for the job, and have both metric and SAE sets on hand to ensure that you are prepared for any job that comes your way.

Common Spline Socket Products

As a professional mechanic, I have worked with various socket sets and tools, including spline sockets. Spline sockets are a specialized type of socket that is designed to tighten and loosen spline fasteners. They are an essential tool for any mechanic or DIY enthusiast who needs to work with spline fasteners.

There are several different types of spline socket products available on the market, each with its unique features and benefits. Some of the most common spline socket products include:

-

Spline Socket Sets: These are complete sets of spline sockets that come in a range of sizes and are designed to fit a variety of spline fasteners. They are an excellent choice for anyone who needs to work with spline fasteners regularly.

-

Individual Spline Sockets: These are individual spline sockets that come in a range of sizes and are designed to fit specific spline fasteners. They are an excellent choice for anyone who needs to work with a specific spline fastener regularly.

-

Spline Socket Adapters: These are adapters that allow you to use a spline socket with a standard ratchet or breaker bar. They are an excellent choice for anyone who already has a standard ratchet or breaker bar and needs to work with spline fasteners.

When choosing a spline socket product, it is essential to consider the size and type of spline fastener you will be working with. It is also important to choose a product that is made from high-quality materials and is designed to last.

Overall, spline socket products are an essential tool for anyone who needs to work with spline fasteners regularly. They are durable, reliable, and designed to make your job easier and more efficient.

Spline Sockets for Fasteners

As a mechanic, I have used many types of sockets, but spline sockets have become a staple in my toolbox. Spline sockets are designed to tighten and loosen both splines and conventional fasteners. They are quite useful and have a larger contact area that allows higher torquing without damaging the corners of the nut.

When it comes to threaded fasteners, spline sockets are a great choice. They are designed to provide a stronger grip on the fastener, reducing the risk of slipping or stripping. Spline sockets are especially useful for square fasteners. They have a series of teeth or ridges that engage with the splines on the fastener, providing a more secure connection than traditional hex sockets.

Spline sockets are also great for lug nuts. These nuts are commonly used on wheels and require a lot of torque to loosen and tighten. Spline sockets provide a secure grip on the lug nut, making it easier to apply the necessary torque.

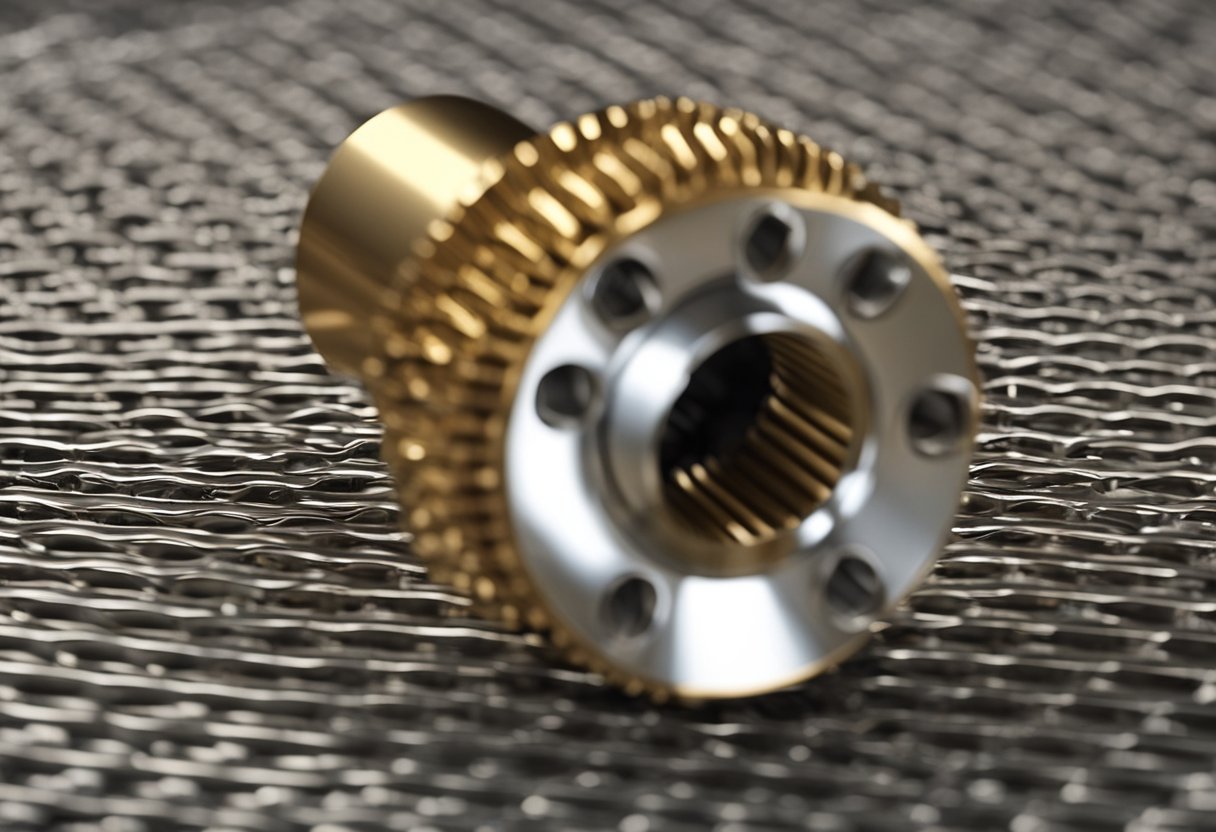

Another great use for spline sockets is with gears. Gears have a spline on their shaft that engages with another gear or a key. Spline sockets are designed to fit into the spline and provide a secure grip, making it easier to install or remove gears.

In conclusion, spline sockets are a versatile tool that can be used in a variety of applications. They are especially useful for threaded fasteners, square fasteners, lug nuts, gears, and keys. With their larger contact area and secure grip, spline sockets are a great addition to any mechanic’s toolbox.

Stress and Torque Management

When it comes to working with fasteners, torque management is a crucial aspect that needs to be considered. The torque applied to a fastener determines its tightness, and if the torque is too high, the fastener can get damaged. This is where spline sockets come in handy. They offer a larger contact area, which allows for higher torquing without damaging the corners of the nut.

Spline sockets also offer better stress management. When a regular socket is used, it grips the corners of the nut, which can cause stress concentration, leading to deformation or even fracture. However, spline sockets avoid gripping the corners, reducing the chance of rounding the nut/bolt, which in turn increases the amount of torque that can be applied.

To understand the importance of surface area in torque management, consider the formula for torque:

Torque = Force x Distance

The force applied to the fastener must be distributed evenly over its surface area to avoid damaging the corners. Spline sockets offer a larger surface area, which allows for even distribution of force and torque.

In summary, spline sockets are a great tool for managing stress and torque when working with fasteners. They offer a larger contact area, which allows for higher torquing without damaging the corners of the nut. They also avoid gripping the corners, reducing the chance of rounding the nut/bolt, which in turn increases the amount of torque that can be applied.

Frequently Asked Questions

What are spline drive sockets used for?

Spline drive sockets are used for tightening and loosening spline-shaped fasteners such as bolts, screws, or nuts. The spline shape resembles a series of teeth or ridges that match up with the corresponding splines on the fastener. Spline drive sockets provide a secure and snug connection between the socket and the fastener, which helps prevent stripping and rounding of the fastener.

What are spline bits used for?

Spline bits are used for driving screws and bolts that have a spline-shaped head. Spline bits have a series of teeth or ridges that match up with the corresponding splines on the fastener, providing a secure and snug connection that helps prevent stripping and rounding of the fastener.

Can spline sockets be used for stripped bolts?

Spline sockets can be used for stripped bolts, but it depends on the severity of the stripping. If the bolt is severely stripped, a spline socket may not be able to grip the fastener properly. In such cases, it is recommended to use a specialized tool, such as a bolt extractor, to remove the stripped bolt.

What is a spline lug nut key?

A spline lug nut key is a tool used to remove and install spline lug nuts. Spline lug nuts are used on some vehicles as a security measure to prevent theft of the wheels. The spline lug nut key has a series of teeth or ridges that match up with the corresponding splines on the lug nut, providing a secure and snug connection that helps prevent stripping and rounding of the lug nut.

Are spline sockets better than regular sockets?

Spline sockets are better than regular sockets in certain situations. Spline sockets have a larger contact area that allows for higher torquing without damaging the corners of the nut. They are also less likely to strip or round off the corners of the nut, which can be a common problem with regular sockets. However, spline sockets are not as versatile as regular sockets and are only suitable for use with spline-shaped fasteners.

What is a male spline socket?

A male spline socket is a socket with a spline-shaped protrusion that matches up with the corresponding splines on a female spline socket. Male spline sockets are used in conjunction with female spline sockets to create a secure and snug connection that helps prevent stripping and rounding of the fastener. Male spline sockets are commonly used in automotive and industrial applications.

Hi, I’m Sal Muller of Tooltrip.com. My DIY experience led me to understand essential power tools for home projects. Tooltrip.com guides enthusiasts and professionals in choosing right tools for any job. I provide concise top tool reviews for easier, efficient DIY.